Research

The Yuan group's research encompasses four major directions: renewable biomaterials, carbon capture and utilization,

integrated biorefining, systems and synthetic biology.

For renewable biomaterial, we have pioneered new chemical fractionation and manufacturing technologies along with

feedstock design to process lignin into quality carbon fibers, bioplastics, recyclable polymer and biodegradable

plastics composites, biodiesel, nanoparticle, asphalt binder modifier and other products. The technology breakthroughs

are based on fundamental understanding of structure-function relationship between lignin chemistry and renewable

material performance. Furthermore, his team have engineered microorganisms to convert lignin and other waste products

into structurally preferred PHA for broad bioplastic applications.

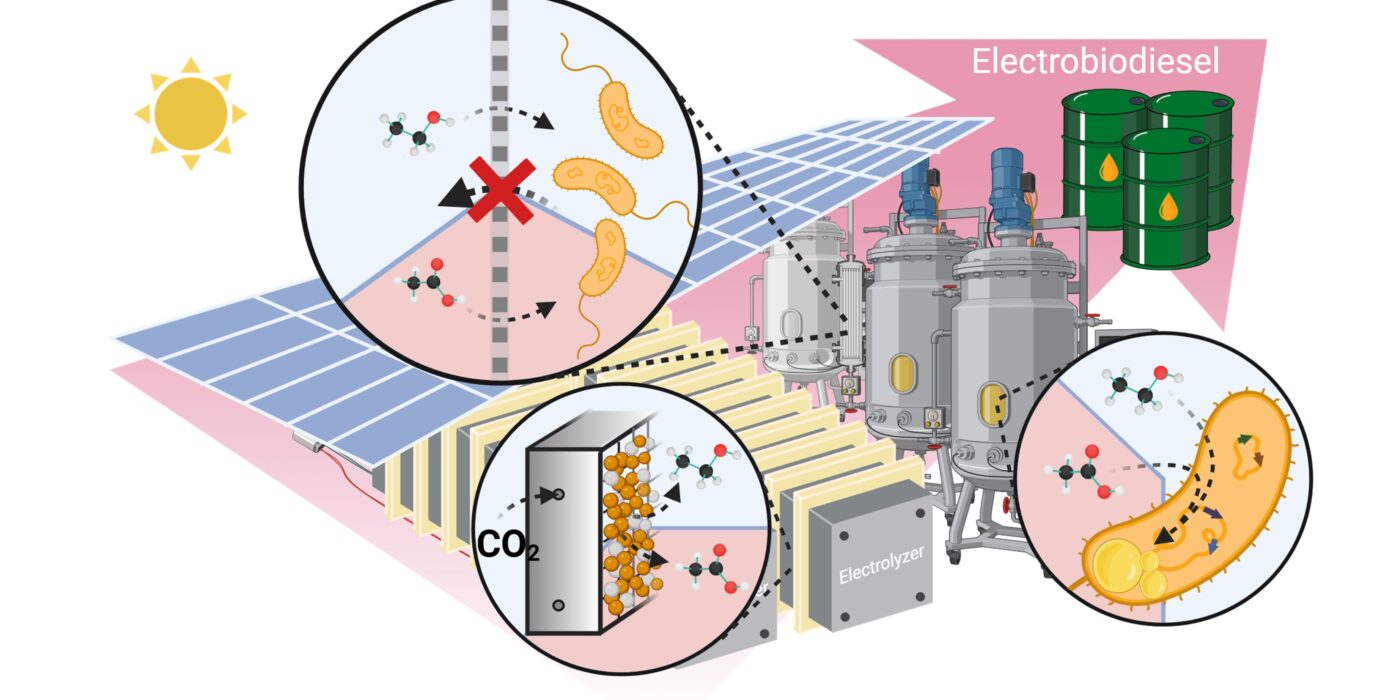

For carbon capture and utilization (CCU), we focused on overcoming the fundamental limits of solar-to-molecule

efficiency in the natural photosynthesis system to achieve efficient carbon capture, conversion, and utilization.

Our research advances two frontiers. First, we advance the chem-bio hybrid route to by-pass Rubisco carbon fixation

with electro- or photo-catalysis to produce biocompatible intermediates for downstream bioconversions. Recent

breakthroughs in EMC2+ (Electro-Microbial conversion with C2+ intermediates) system have surpassed the solar-to-molecule

energy efficiency in natural photosynthesis by multiple folds, achieving very efficient carbon capture and conversion.

Second, we have addressed several major challenges in algal carbon capture and utilization. We have integrated artificial

intelligence and synthetic biology to develop continuous algal cultivation technologies achieving the highest reported

outdoor productivity. Based on this technology, they are advancing novel CCU platforms for flue gas, direct air capture,

and various other CO2 emissions. We also developed auto-sedimentation to reduce the harvest cost substantially.

For integrated biorefining, our team addressed the dilemma of "lignin-first" and "carbohydrate-first" processes and

designed novel biorefining procedures to synergistically derive more processable lignin and carbohydrate. Together with

the biomaterial design and synthetic biology, these engineering technologies could potentially enable the integrated

biorefinery with multiple product streams for profitability and sustainability.

For systems and synthetic biology, Professor Yuan's team advanced the fundamental understanding of photosynthetic

carbon repartition from sugar metabolism to terpene biosynthesis. The research has led to the sustainable manufacturing

platform for squalene, an essential vaccine adjuvant, cosmetic and nutraceutical product. The research also empowered

efficient biomass processing and algal biofuels and bioproduct manufacturing.

People

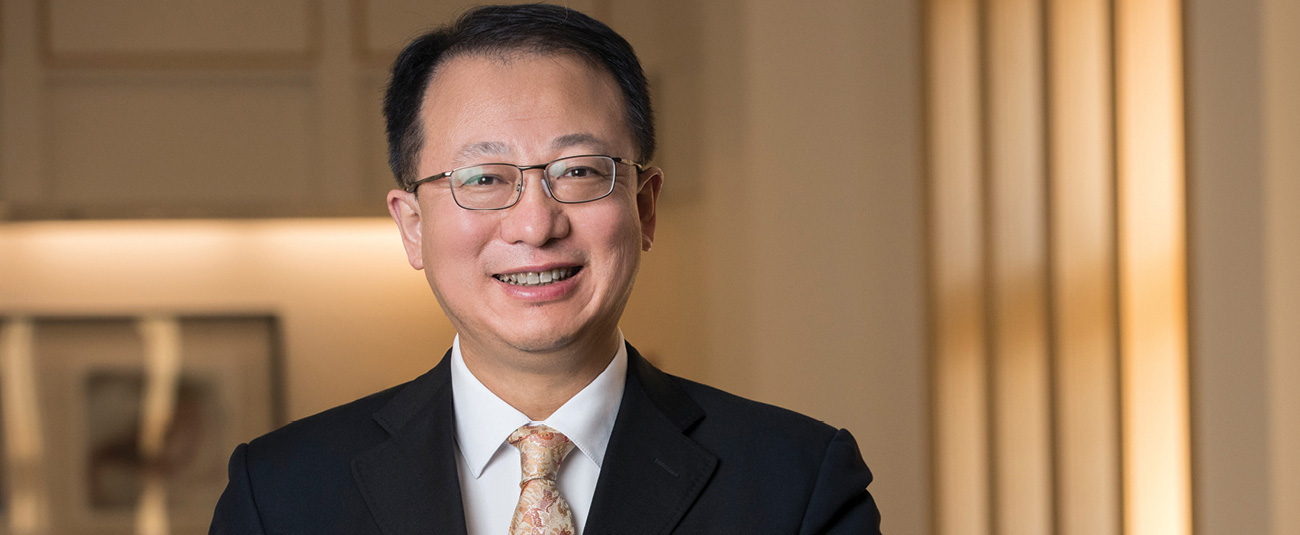

Joshua S. Yuan, Ph.D.

Lucy & Stanley Lopata Professor and Chair, Department of Energy, Environmental, and Chemical Engineering, The McKelvey School of Engineering, Washington University in St. Louis

Joshua Yuan serves as the Lucy & Stanley Lopata Professor, the Chair for the Department of Energy, Environmental and Chemical Engineering, and the Director of Carbon Utilization Redesign through Biomanufacturing (CURB) NSF Engineering Research Center at Washington University in St. Louis. Previously, he was a faculty member at Texas A&M University since 2008 and was appointed as the Chair for Synthetic Biology and Renewable Products in 2018. He has served as the Director of the Synthetic and Systems Biology Innovation Hub since 2015. Joshua has built a career in developing, disseminating, and implementing sustainability solutions for the future. His research focuses on CO2 utilization, renewable biomaterials, biomass processing, and biorefining, as well as synthetic and systems biology. He has been awarded four U.S. patents and has five pending. He has written more than 100 peer-reviewed journal articles, published in Joule, Chem, Matter, One Earth, Nature Communications, Green Chemistry, Advanced Sciences, and PNAS, among others. He is now a Fellow of the Royal Society of Chemistry.

Scientists and Postdocs

Le Zhou

- Postdoc Researcher, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis, Google Scholar

- Ph.D. in Chemical Engineering from Institute of Process Engineering, Chinese Academy of Sciences in 2022. Research focuses on lignocellulosic biomass biorefinery using green solvents and the development of renewable biomaterials.

Weiwei Li

- Postdoc Researcher, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis, Google Scholar

- Ph.D. at University of Chinese Academy of Sciences. Research focuses on leveraging biomass and microbial processes to engineer high-value carbon materials for applications in environmental remediation and energy conversion and storage.

Qikun Hu

- Postdoc Researcher, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis, Google Scholar

- Ph.D. at National University of Singapore, 2020-2024. Research focuses on electroctatlysis of nitrogen and carbon chemistries.

Graduate Students

Puneet Dhatt

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis, Google Scholar

- B.S. in Biochemistry from the University of Michigan in 2021. Research focuses on designing biomimetic materials and leveraging synthetic biological tools for bioproduct synthesis.

Yuanhao Liang

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis

- Research focuses on synthetic biology for novel bioconversion pathways.

Yanyi Wen

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis

- Second-year Ph.D. student, working on algae-derived materials and functional biomaterial design.

Wentao Dai

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis, Google Scholar

- B.S. in Environmental Engineering and M.S. in Energy, Environmental, and Chemical Engineering from Washington University in St. Louis.

- I joined the Yuan Group to explore innovative methods that bridge electrochemical CO2/CO reduction and biomanufacturing, aiming to develop sustainable, practical solutions for real-world applications. Outside the lab, I enjoy flying drones, playing tennis, and working on 3D printing projects.

Wei Wei

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis, Google Scholar

- B.S. in Materials Science and Engineering from Wuhan University of Technology in 2022. Joined Yuan Research Group in 2022 pursuing a Ph.D. with research related to electrocatalysis.

Alzira Pereia

- Visiting Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis, Google Scholar

- B.S. in Biology from the Federal University of Ouro Preto (UFOP), Brazil, in 2022. Currently pursuing a Ph.D. in Industrial Biotechnology at the University of São Paulo (USP), Brazil, with research focused on lignin valorization. During her undergraduate studies, she took part in a scientific initiation program in the fields of immunopathology and molecular biology.

Isaac Hazlehurst-Johnson

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis

Haina Lan

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis

- My research focuses on the development of cell-free catalysis systems, functional bio-materials for drug delivery, and the development of value-added bio-products. In my spare time, I like to go hiking, swimming, and play with my cat.

Kevin Li

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis

- B.S. in Chemical Engineering from Washington University in St. Louis, 2024.

Vincent Xu

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis Google Scholar

- B.S. in Chemical Engineering from Washington University in St. Louis, 2024. Research focuses on metabolic modeling and bioprocess engineering for cell-free enzymatic reaction system design, cell-based strain optimization, and enzyme design. Special consideration is taken for utilization of modeling techniques to enhance industrial feasibility of bioprocesses.

Corin Huang

- Ph.D. Student, Department of Energy, Environmental, and Chemical Engineering, Washington University in St. Louis, Google Scholar

- B.S. and M.S. in Biochemical Science and Technology, National Taiwan University. Research focuses on synthetic biology and metabolic engineering; more specifically, algae-based biomaterial production and nitrogen fixation processes incorporating with electrocatalyst-based CO2 fixation.